PTFE Piston Cup Seals

PI filled ptfe piston cup seals

PTFE PISTON CUP SEALS

PTFE (Polytetrafluoroethylene) Piston Cup Seals are specialized components used in various applications where low friction, chemical resistance, and high wear resistance are crucial. They are commonly found in oil-free air compressors, air pumps, vacuum pumps, and atomizers, serving as seals to prevent fluid leakage..

Inquire Now

Descriptions

PI FILLED PTFE CUPS SEALS APPLICATION

Compressor Systems :

Spring-Energized Seals :

Rotary and Reciprocating Sealing :

Stop-Start Applications :

Cryogenic and High Temperature Environments :

Vacuum and Low Outgassing Requirements :

Abrasion Resistance :

PTFE RAW MATERIAL PROPERTY

Polytetrafluoroethylene (PTFE), commonly known as Teflon, possesses several remarkable properties that make it suitable for various applications. Some of its key characteristics include:

- Chemical Resistance: PTFE is highly resistant to almost all chemicals, acids, bases, and solvents, making it ideal for use in harsh chemical environments.

- Non-Stick Surface: Its low surface energy results in a slippery surface, preventing substances from adhering, which is beneficial in cookware and industrial applications.

- High Temperature Resistance: With a high melting point around 327°C (620°F), it maintains stability and functionality at elevated temperatures.

- Low Coefficient of Friction: PTFE has one of the lowest coefficients of friction, reducing wear and energy loss in sliding applications.

- Dielectric Properties: It is an excellent electrical insulator, with high dielectric strength and a low dielectric constant.

- Non-Toxic and Biocompatible: Safe for use in medical implants and food contact applications.

- Low Thermal Conductivity: PTFE provides good thermal insulation due to its low thermal conductivity.

- Lightweight and Strong: Despite its low density, PTFE is strong and durable, with good tensile strength and fatigue resistance.

- Non-Flammable: PTFE is self-extinguishing and does not support combustion, making it fire-resistant.

- UV Resistance: It is resistant to UV degradation, ensuring stability and performance in outdoor applications.

PTFE raw material is available in different grades and forms, such as powders, pellets, and sheets, which can be modified with fillers like glass, carbon, or molybdenum disulfide to tailor its properties.

PTFE PROCESSING METHOD

Planer, Drilling, Milling and other machining methods

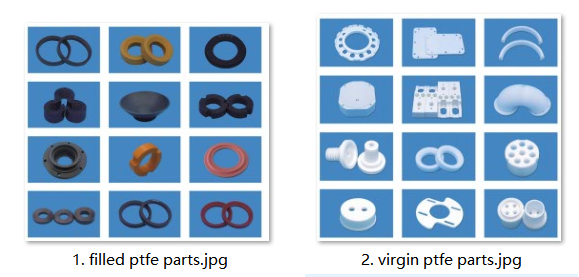

RELATED PTFE PARTS

FAQs

We are making our greatest efforts to offer you the quality rubber seals and plastic parts products at good price. We’d like to cooperate with you to expand our business in your markets.If in doubt, please see the following FAQs

Q: Are you a trading company or manufacturer ?

Q: what do you need for a free quote ?

Q: what is your leadtime normally ?

Q: what is your MOQ ?

Q: How about your payment terms ? How do I pay you ?

Get a free quote

Please give us a message for your enquiry . order or advice. Thanks a lot.

Send Message